Wollastonite – High-performance fillers with reinforcing properties

In summary: Wollastonite, the natural calcium silicate mineral

Wollastonite is a mineral from the silicate group. It was named in honor of the English chemist and mineralogist William Hyde Wollaston. Wollastonite is refined for use as a filler in various industrial sectors, such as the production of ceramics, building materials, glass, paints, plastics, and metals. Wollastonite can be found in various parts of the world, including China, Mexico, India, Spain and the USA.

Chemistry and Mineralogy

Wollastonite forms at about 450°C through the reaction between silica and calcium carbonate. The structure of individual wollastonite particles is influenced by both their geological origin and the processing technology applied.

- The crystal structure of wollastonite appears as a chain inosilicate.

- Wollastonite is a widely distributed mineral with the chemical composition CaSiO3. It belongs to the class of silicate minerals. Its crystal structure consists of chains of (SiO3)2 − bonded together by calcium cations.

- Wollastonite crystallizes colorless in the triclinic crystal system. It forms through the contact metamorphosis of limestone and is an integral component of the metamorphic rock Skarn.

Technical properties in summary

- Wollastonite has a Mohs hardness of 4.5 and a density of 2.85 g/cm³.

- Thanks to its low coefficient of thermal expansion of 7*10-6/K in the temperature range from 20 to 300 °C, it is suitable for applications with variable temperature conditions.

- Wollastonite shows excellent reinforcing properties, making it a valuable material in various industrial sectors.

- Additionally, it is chemically inert, meaning it is resistant to many chemicals.

Wollastonite from HPF: high-quality products

The products distributed by HPF carry the following brands:

TREMIN®

surface treated products

Aspect ratio: the aspect ratio of wollastonite

The length-to-diameter ratio, also known as the "Aspect Ratio," varies depending on the origin and production process of the wollastonite. We offer two main product lines:

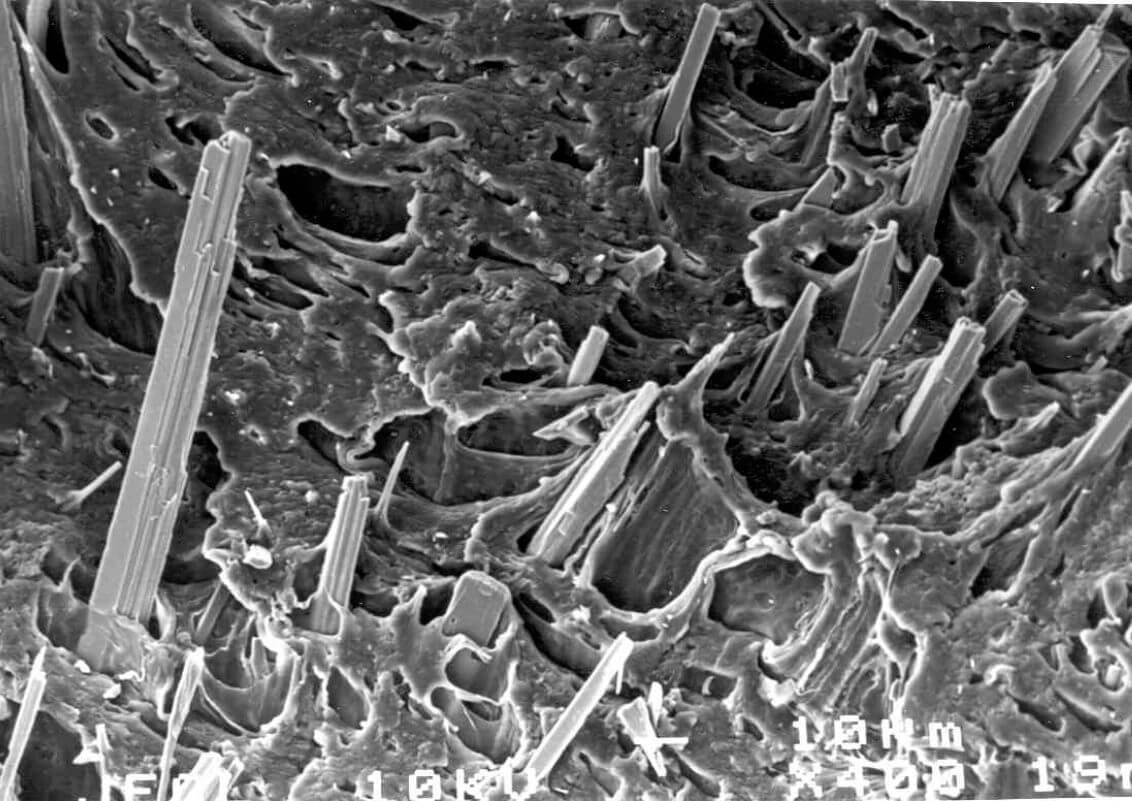

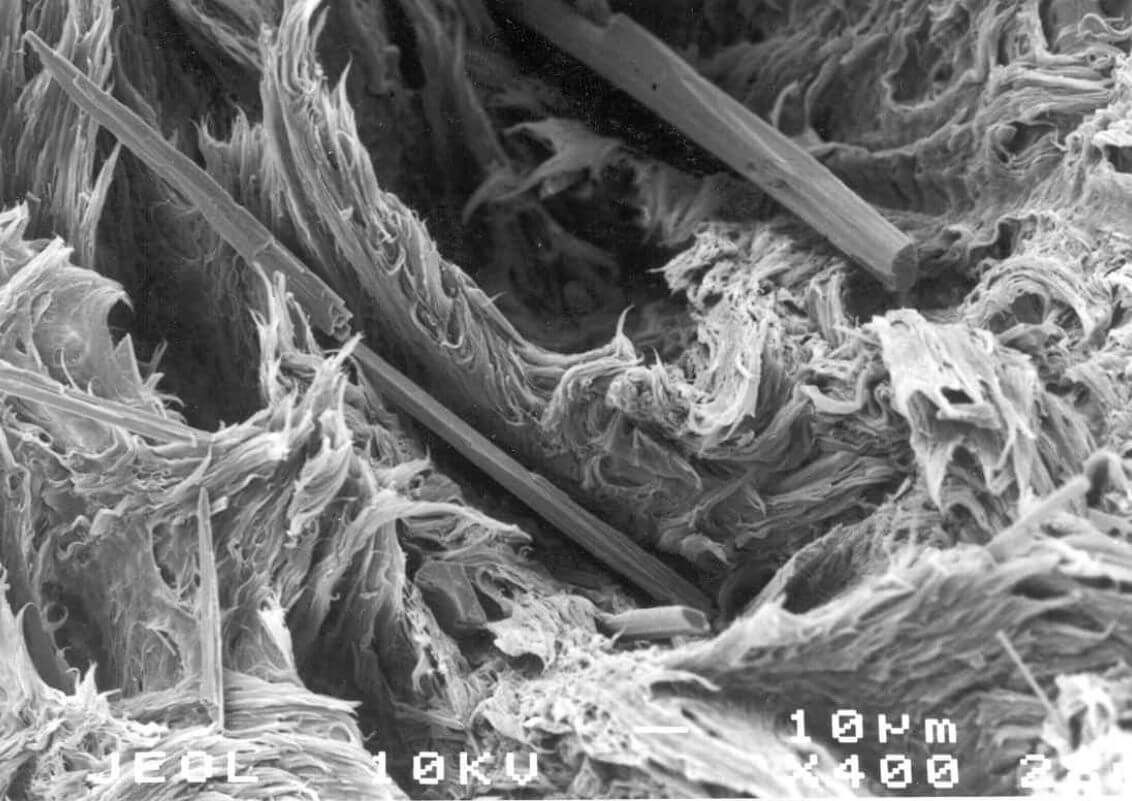

The "Low Aspect Ratio" (LAR) product line, represented by TREMIN® 283, is characterized by blocky particle shapes with a low length-to-diameter ratio of 3:1.

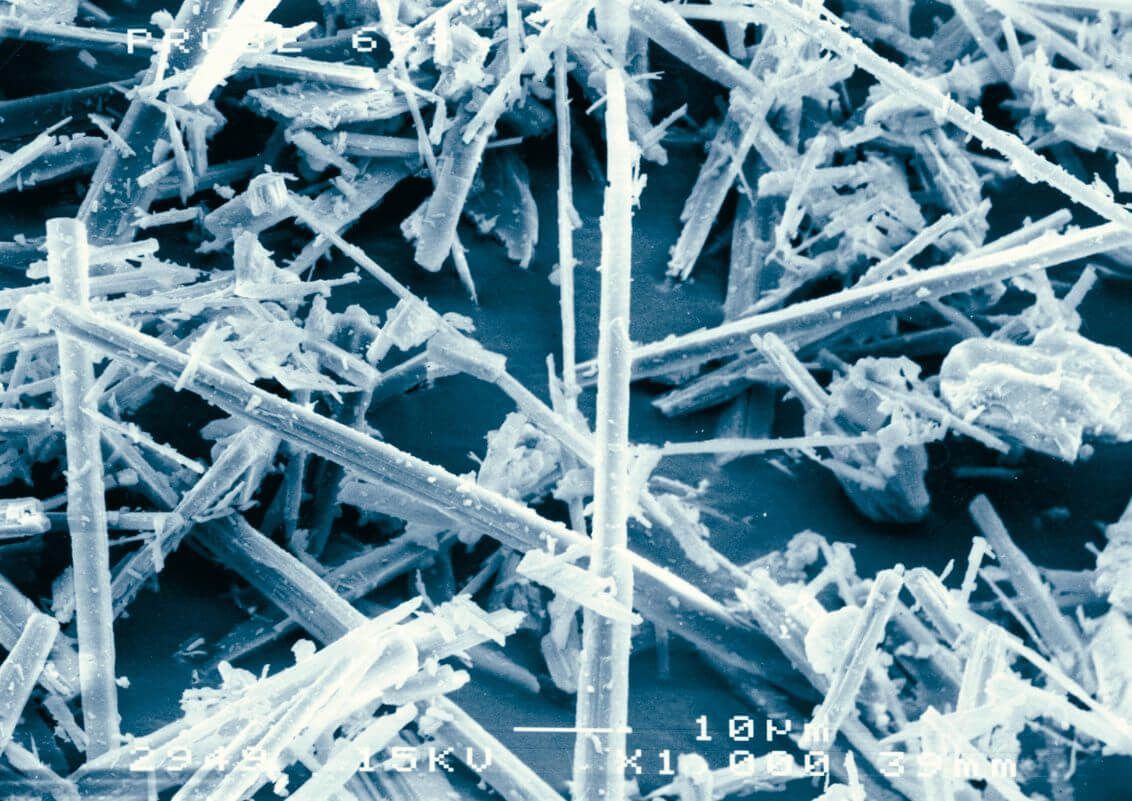

On the other hand, the "High Aspect Ratio" (HAR) product line, represented by TREMIN® 939, features highly needle-shaped wollastonite particles with a high length-to-diameter ratio of 8:1.

Thanks to a special plant technology, the needle shape of the HAR wollastonite is maintained even after grinding and is clearly visible under a microscope.

TREMIN® 283 SILANIZED (WOLLASTONITE LAR)

TREMIN® 283

TREMIN® 939 SILANIZED (WOLLASTONITE HAR)

TREMIN® 939

Surface treatment of wollastonite

Through a targeted surface modification, better corrosion protection can be achieved: the use of surface treated wollastonite TREMIN® in epoxy resin-based powder coatings for external metal coatings offers various improvements. These include increased effectiveness in corrosion protection, better hot water resistance, optimized filling levels, and increased resistance to cathodic delamination. Effective corrosion protection helps to reduce the frequency of maintenance operations on plants and buildings and prevent the premature replacement of high-maintenance components, which are often exposed to high humidity or pollutants.

OUR WOLLASTONITE – AN IMPORTANT RAW MATERIAL FOR POLYMER APPLICATIONS

Wollastonite is used in various polymer sectors: in technical plastics for the automotive industry, wollastonite helps improve mechanical properties. The TREMIN® 283 product series is used in fluor elastomers, particularly in oil seals, where they stand out for their chemical resistance and elasticity.

Technical plastics

Polypropylen

Polypropylene is used in a wide range of applications. In polypropylene systems, the excellent reinforcing properties of needle-shaped wollastonite TREMIN® 939 have been demonstrated for years. Surface-modified TREMIN® 939 types can be optimally incorporated into the polymer. Polypropylene compounds produced with TREMIN® 939 are characterized by excellent impact resistance and high rigidity. Additionally, they offer high heat resistance and low shrinkage, prerequisites for the "Zero-Gap-Design."

Polyamid

Polyamide 6 and Polyamide 66 are the most widely used technical plastics in the world. Short needle wollastonite flours, coated with amino silane, TREMIN® 283, have been successfully used for many years as functional fillers for polyamides when deformation-free properties are required. Superior stiffness can be achieved with long needle TREMIN® 939 grades. Reinforced polyamides offer a variety of possibilities for the construction of rigid, deformation-free molded parts, used for example in hubcaps, engine covers, air filter housing, and electrical equipment parts. The reinforced compounds are characterized by excellent rigidity, high heat resistance, and excellent dimensional stability.

PUR-RRIM

Automotive parts filled with long needle wollastonite TREMIN® 939 offer high tensile strengths, good optical properties, and very good suitability for high-gloss paints. With the right dosage, the modulus of elasticity can be perfectly adjusted.

Thermoset polymers – HPF Minerals

Fluoro elastomers

Fluoro elastomers are highly specialized materials for the most demanding applications in engine and machine engineering, as well as in the construction of chemical plants. Our short needle wollastonite flours, surface treated, have been successfully used for many years as functional fillers in fluoro elastomers, for example, to regulate hardness. In fluoro elastomers, our TREMIN® 283 products offer, in addition to good reinforcement, the advantage of clear and colorable mixtures. Fluoro elastomers optimized with TREMIN® 283 are ideal for applications under special conditions, such as high mechanical and chemical stresses

Paints and coatings

Corrosion protection

The corrosion protection of epoxy resin-based powder coatings for external metal coatings is significantly improved by using surface treated wollastonite. Additionally, the wollastonite flours used increase scratch resistance and weather resistance. In single-layer 2K-EP coatings, the use of a filler combination with TREMIN® 283 can completely or partially replace the anticorrosive zinc phosphate pigment. Our high-performance fillers thus offer an ecological and economical solution for formulating corrosion protection coatings without zinc, for example for the construction industry, agricultural equipment, construction machinery, or parts exposed to aggressive climatic conditions.

Industrial coatings – HPF Minerals

Coatings for offshore rotor blades

Successfully passed tests confirm that the addition of TREMIN® 283 with a surface coating adapted to the polymer system in a rotor blade coating system improves resistance to adverse weather conditions at higher rotation speeds.

Traditional standard applications of wollastonite

An important area of wollastonite use is the ceramics industry, where minerals improve the mechanical properties of white ceramics. Typically, it is also used in welding electrodes, insulating materials, and flame-resistant protective clothing.

The properties of wollastonite

The category of inosilicates, to which wollastonite belongs, includes minerals whose silicate anions form infinite chains or ribbons of SiO4 tetrahedra connected at the corners. The linear structure of the silicate chains is reflected in the properties of inosilicates. The crystals show low symetry, mainly triclinic, monoclinic, or orthorhombic, but never cubic. The prismatic to needle-like shape of the crystals extends along the silicate chains, and cleavage in this direction is generally very good.

Wollastonite exhibits interesting properties: it is insoluble in water but shows good solubility in saltwater. Under certain conditions, it can fluoresce. The typical shape ranges from needle-like to fibrous, and the mineral can be either colorless or milky white. It crystallizes in the triclinic crystal system. Another remarkable feature is the low thermal expansion of wollastonite.

The history of wollastonite

The term "wollastonite" was first introduced in 1818 by J. Léman when describing rocks. It is interesting to know that the first description of the mineral already took place in 1793 by the Austrian mineralogist Andreas Stütz in his work "Neue Einrichtung der k.-k. Naturalien-Sammlung zu Wien." On that occasion, he used the name "Tafelspath" for the mineral.

The rock samples probably came from the Romanian part of Banat, although this is not clearly documented. The name change from Tafelspath to Wollastonite by Léman was made in honor of the scientific merits of the famous English naturalist William Hyde Wollaston (1766–1828).

FAQ

Which properties does wollastonite have?

Wollastonite is a calcium silicate mineral (CaSiO₃) with a hardness of 4.5 to 5 on the Mohs scale and a density of about 2.86 to 3.09 g/cm³. It has a needle-like crystal structure, high chemical resistance, and low thermal expansion, making it temperature stable. Additionally, wollastonite is not water-soluble and has high whiteness.

For what applications can you use wollastonite?

Wollastonite is used in the ceramics industry as a flux to reduce firing temperature and improve strength. In the plastics and rubber industries, it is used as a filler to increase stiffness and heat resistance. In paints and coatings, it enhances durability and coverage. Additionally, it serves as a slag conditioner in metallurgy and as a substitute for asbestos in the construction industry.

How does wollastonite work?

Due to its needle-like structure, wollastonite increases the mechanical strength and stiffness of plastics and composites. In ceramic products, it lowers the firing temperature and reduces shrinkage. In paints and coatings, it improves weather resistance and provides a smooth surface. Its thermal stability makes it ideal for refractory applications.

How is wollastonite produced?

Naturally, wollastonite forms through contact metamorphism when calcium-rich rocks like limestone or dolomite react with silicon-rich solutions. Industrially, it is extracted from deposits, crushed, purified, and classified. For specific applications, it can be surface-treated to improve its adhesion in plastics or other materials.

MORE INFORMATION?

For all questions regarding wollastonite, we are happy to assist you. Please do not hesitate to contact us – we will be happy to respond.