Fused silica: The mineral with extremely low thermal expansion

Fused silica – the amorphous modification of silica

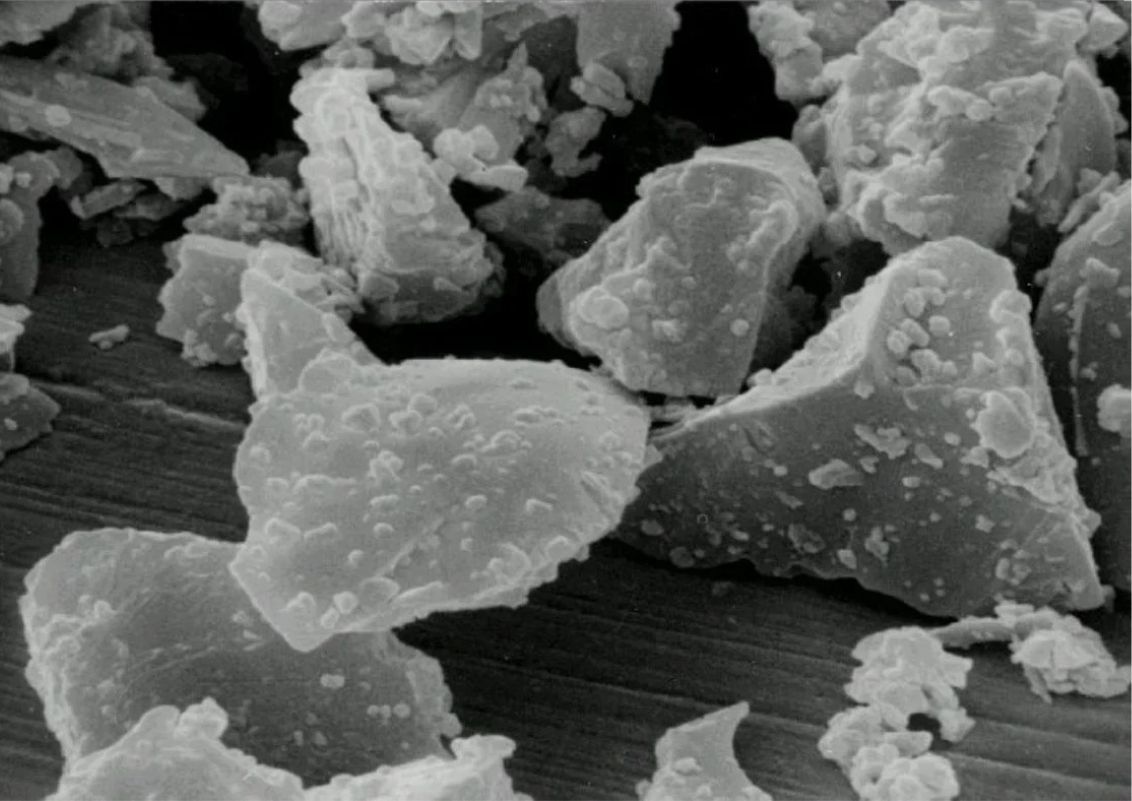

Fused silica represents the amorphous variant of silica, synthetically produced in the electric arc at around 2,000°C. Subsequently, the amorphous silica glass thus obtained is finely ground. Through iron-free grinding and subsequent screening processes, we produce various particle sizes of fused silica. In addition to standard products, we offer a special variant optimized for grain size.

An exceptional feature of fused silica is its extremely low coefficient of thermal expansion, which is crucial for special applications subjected to strong temperature fluctuations.

Minimum coefficient of expansion: The technical properties of fused silica

Fused silica impresses with its exceptional technical properties. With a hardness of 6.5 on the Mohs scale, a density of 2.2 g/cm³, and chemical inertia, it is a robust and resistant mineral. Particularly impressive is the extremely low coefficient of thermal expansion of 0,5*10⁻⁶/K in the temperature range from 20 to 300°C.

These unique characteristics make fused silica an indispensable choice for multiple industrial applications.

Chemical formula and mineralogy

Regarding the modifications of the chemical formula of silicon dioxide (SiO2), fused silica belongs to the group of oxide minerals, along with silica and cristobalite. Although all three share the chemical composition SiO₂, they differ in the method of production, certain technical parameters, and various fields of application.

HPF's fused silica products: highest quality products

The fused silica products distributed by HPF bear the following trade brands:

AMOSIL®

untreated fused silica

BRUCAFIL®

special fused silica

SILBOND®

surface-treated fused silica flour

SILMIKRON®

ultra-fine fused silica flour in untreated and treated form

Below, we present our products in more detail.

AMOSIL®

Under the brand AMOSIL®, we distribute our types of untreated fused silica. These are available in coarse particle sizes as well as finely ground versions.

BRUCAFIL®: Highly special in the best sense

The BRUCAFIL® range of our fused silica products is ideal for the production of electronic components and parts, especially when low viscosities, optimized particle size distributions, and adapted grain shapes are required.

Main applications

- EMC / CCL

- Microprocessors

Properties

- Narrow classifications

- Adapted grain shape

- Low viscosities

SILBOND®

Surface treated fused silica flour under the brand SILBOND® is used in demanding applications with high requirements. These include electronics and electrical insulation, casting resin systems, and investment casting.

SILMIKRON®: Highest quality fused silica flour

Our product SILMIKRON® 1171 features synthetic amorphous silicon dioxide, comparable to fumed silica. This extremely fine product stands out for its high purity and minimal BET surface area.

Main applications

- Technical rubber parts

- Paints

Properties

- High purity

- d50 = 0.3 μm

- Specific surface area (BET) of 30 m2/g

Our fused silica – important raw material for polymer applications in electrical engineering and electronics

Epoxy resin has been one of the most important raw materials in electrical engineering and electronics for many years due to its excellent adhesion, resistance to heat and chemicals, and outstanding electrical properties.

In electronics, materials based on epoxy resin are used as encapsulation systems, lamination resins for circuits, and as auxiliaries in the production of printed circuit boards. In electrical engineering, epoxy resin is used in the construction of transformers and in the production of insulators and dry-type transformers.

The mechanical, thermal, and electrical properties of epoxy resin largely depend on the chosen functional fillers.

Epoxy casting masses and metallic materials in electrical engineering are subject to high thermal stress. To prevent damage, the dimensional changes due to temperature of the different materials must be as similar as possible.

The targeted use of selected SILBOND® fused silica flours minimizes these differences, enables the production of complex components, and prevents crack formation. For higher degrees of filling, we recommend the grain size optimized type SILBOND® FW 126 EST for higher filling degrees.

Our products offer the following properties in applications with epoxy resins:

- Improved weather and chemical resistance

- Good mechanical resistance

- Excellent workability

- Extremely low thermal expansion

- Reduced shrinkage

- High degrees of filling

Silanes for surface treatment of fillers: advantages of surface treatment

Various silanes have proven effective in surface treatment of fillers. A significant advantage of direct surface treatment is that condensation by-products can escape during coating of the mineral. Unlike subsequent in situ surface treatment, direct surface treatment does not leave any by-products in the polymer system.

The use of coated fillers facilitates incorporation into a polymer compared to uncoated ones. To ensure optimal bonding between the polymer and the high-performance filler, a coating agent specifically adapted to the polymer system is required. This adaptation not only ensures better integration but also optimal performance of the entire composite material.

The history of fused silica

The history of fused silica is closely linked to silica, one of the most common minerals on our planet. Indeed, silica is the main component of fused silica. It is an amorphous modification of quartz and is produced synthetically. The use of silica or silicon dioxide in various applications has a history going back thousands of years. It has been used in numerous cultures for various purposes, from jewelry to building materials. The development of amorphous silica or silica glass through synthetic processes only occurred during the 20th century.

The use of fused silica in major fields of application such as electronics, electrical engineering, and optics has been promoted by the unique properties of the material, particularly its extremely low thermal expansion and high purity. Research and development in materials science, as well as user companies, continuously work to discover new application possibilities. The future of fused silica as a filler for the industry remains exciting!

FAQ

What properties does fused silica have?

Fused silica, also known as quartz glass, is an amorphous material produced by melting high-purity silica. It is characterized by its high resistance to high temperatures, low thermal expansion, and excellent optical transparency in the UV and visible spectrum. Additionally, it has high chemical purity and resistance to many chemicals.

In what applications is fused silica used?

Fused silica has multiple applications in the chemical industry, particularly as a replacement for sand baths or supports. It is also used for coatings and furnace inserts.

What benefits does fused silica have?

The effectiveness of fused silica in these applications is based on its high resistance to high temperatures and low thermal expansion, which allows it to withstand strong temperature fluctuations without breaking or deforming. Its chemical purity and resistance make it ideal for use in environments containing aggressive chemicals.

How is fused silica produced?

The production of fused silica is achieved by melting high-purity quartz at temperatures above 1,700°C. The molten material is then shaped into sheets, tubes, or other forms, depending on the intended application. This process requires special equipment and controlled conditions to ensure the purity and quality of the final product.

More Information?

For all questions regarding fused silica, we are gladly at your disposal. Please do not hesitate to contact us – we will be happy to respond.