Anhydrite: Versatile Mineral with Exceptional Moisture Resistance Properties

Useful information about Anhydrite

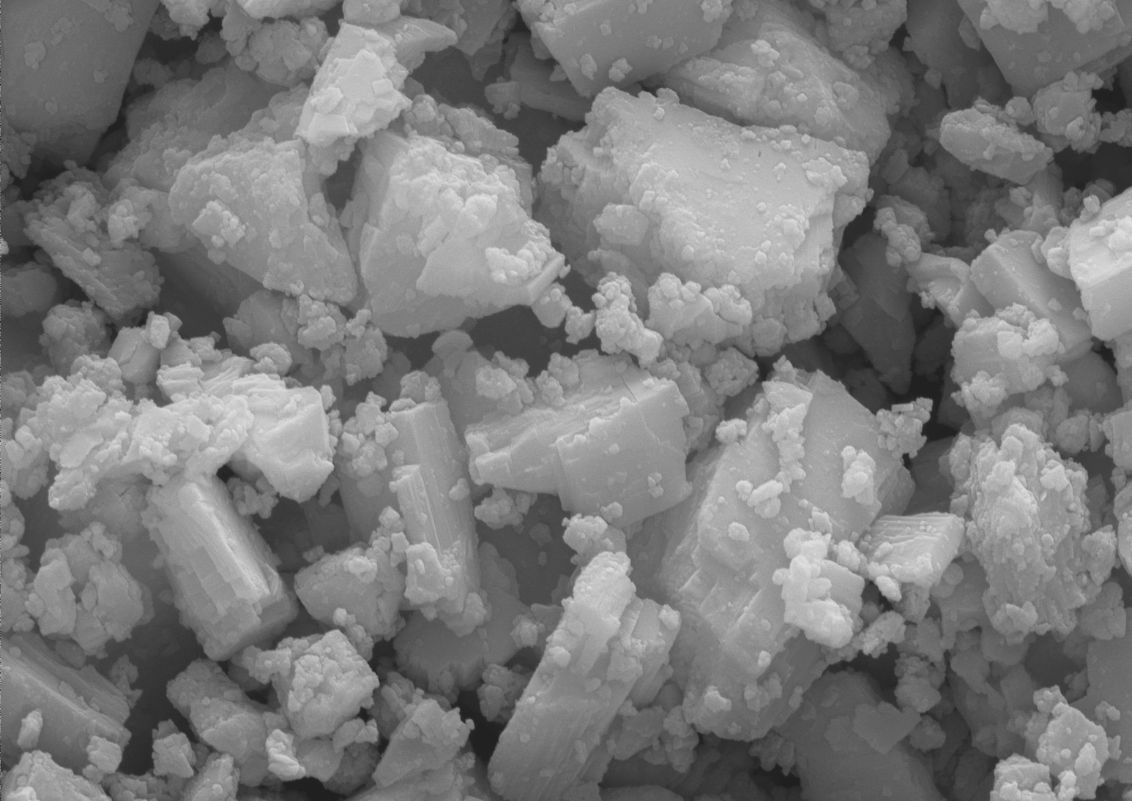

Anhydrite is a sulfate mineral found in various geological formations worldwide. It often appears as transparent or translucent crystals. This mineral is known for its versatility and is valued in various industries. Particularly noteworthy is its use as a moisture-resistant filler in the construction industry. The mineral is also found in the chemical industry. A particularly remarkable site of discovery is Chihuahua in Mexico, where impressive crystals of anhydrite (20 cm) have been found. However, there are deposits in Germany and many other countries around the world.

Technical properties

- hardness 3,5 (Mohs)

- density 3.0 g/cm3

- high whiteness

- tabular structure

- good transparency

CHEMISTRY AND MINERALOGY

Chemical formula: CaSO4

Anhydrite belongs to the group of anhydrous sulfates and forms the stable body of gypsum deposits. It crystallizes in the orthorhombic crystal system and forms prismatic crystals.

Anhydrite from HPF: High-quality products

The products distributed by HPF bear the brand:

TREFIL® 1313

untreated and surface treated

The untreated TREFIL® 1313 anhydrite powders are available in various types of fines, allowing optimal adaptation to the specific needs of our customers. Surface treatment with silanes can improve adhesion and facilitate dispersion in various matrix materials such as plastics, resins or coatings.

What are industrial minerals like anhydrite?

Industrial minerals are mineral raw materials used directly for industrial purposes without prior transformation. Extraction typically includes washing and classifying the minerals. Further processing steps such as grinding or surface treatments can also be performed. The use of industrial minerals takes place due to their nature and specific properties. The application possibilities vary depending on the characteristics of the mineral, such as hardness, density or shape.

The advantages of surface treated anhydrite

Different silanes have proven effective in surface treatment of fillers. An important advantage of direct surface treatment is that condensation by-products can escape during mineral coating. Unlike subsequent in situ surface treatment, direct surface treatment leaves no by-products in the polymer system.

Coating anhydrite with silanes modifies the surface, improving adhesion. Coated fillers can be more easily integrated into a polymer compared to uncoated fillers, improving processing and material homogeneity. However, optimal bonding between polymer and high performance filler requires a coating agent specifically adapted to the polymer system.

The TREFIL® 1313 anhydrite products are also available in surface treated form, offering customers a wide range of options for their needs. These surface treated anhydrite products offer improved adhesion and compatibility with polymers, leading to high-quality end products.

Our anhydrite – Important raw material for polymer use

Good transparency on wood thanks to anhydrite

PLASTIC FILMS

In PP and PE films, anhydrite offers excellent anti-block properties combined with high UV transmission values and good aesthetics.

PAINTS AND COATINGS

Transparent UV paints are widespread in the furniture industry and parquet painting. Coatings for panels often do not tolerate hard and abrasive fillers due to metal abrasion caused, for example, by conveyor rolls. With the high-performance filler TREFIL® 1313-600 based on natural anhydrite, we offer a filling solution for these UV paint applications. Even in 2K PU transparent paints, TREFIL® 1313 has proven effective due to its good transparency properties. Using this product significantly improves adhesion and, thanks to the low Mohs hardness of anhydrite, ensures good grindability

High solid systems are an excellent solution for formulating paints with reduced volatile organic compound (VOC) content. With TREFIL® 1313-600 and a surface treated variant, based on natural calcium sulfate (anhydrite), formulation possibilities with good optical, mechanical and corrosion protection properties are offered, reducing VOC content.

The main properties of anhydrite

Anhydrite is known for its moisture resistance, medium hardness and chemical stability. It crystallizes in the orthorhombic crystal system and forms prismatic crystals. The transparency of anhydrite makes it suitable for transparent coatings. The refractive index is similar to that of many polymer components; anhydrite has low birefringence.

With a Mohs hardness of about 3 - 3.5 and a density of about 2.9 - 3.0 g/cm³, anhydrite offers some resistance to abrasion and wear. Due to its white-gray color and tabular structure, it is a suitable material for the production of paints, plasters and coatings. Anhydrite is poorly soluble in water and well cleavable.

Formation and deposits of anhydrite

Anhydrite generally forms through the evaporation of seawater or through hydrothermal processes in rocks. It is often found in gypsum deposits as a product of gypsum diagenesis, where gypsum is transformed into anhydrite by loss of crystalline water. These processes typically occur in shallow marine basins where evaporation rates are high and the concentration of dissolved minerals increases.

The formation of anhydrite is closely related to geological conditions that provide sufficient concentrations of calcium and sulfate ions as well as adequate levels of pressure and temperature.

Some of the most significant anhydrite deposits are found in Germany, France, Italy, the United Kingdom, the United States and Canada. In addition to these major deposits, there are numerous minor deposits worldwide, often associated with other mineral deposits.

The history of anhydrite

The history of anhydrite starts in the late 18th century: the mineral was discovered in 1794 by Nicolaus Poda von Neuhaus, an Austrian entomologist. Assuming it was hydrochloric limestone, he erroneously named it "Muriacid".

When it was discovered that the mineral was actually sulfate limestone, the French mineralogist René Just Haüy proposed the name chaux sulfatée anhydre (anhydrous sulfate limestone) in 1801.

A year later, the final name was established by Abraham Gottlob Werner, a German geologist who wrote the "Manual of Mineralogy". The name "Anhydrit" has remained to this day.

Over time, new properties and applications of anhydrite have been discovered. Today, this versatile mineral is considered an important raw material for industry in many sectors.

Useful information about other industrial fillers

Use our information guide to learn more about other fillers for industrial purposes. We are happy to provide information in person.

FAQ

What properties does anhydrite have?

Anhydrite is an anhydrous calcium sulfate (CaSO₄) that crystallizes in the orthorhombic crystal system. It usually appears colorless or white but can take on blue, red or purple hues due to impurities. With a Mohs hardness of 3-3.5 and a density of about 2.98 g/cm³, it is a brittle mineral with perfect cleavage.

In which applications you can use anhydrite?

In the construction industry, anhydrite is used as a component in cement and for the production of calcium sulfate-based binders for screeds. It is also used for the production of sulfuric acid and cellular concrete.

What benefits does anhydrite have?

Anhydrite acts as a binder in screeds, which hydrates and hardens when water is added, transforming into gypsum. This process leads to high-strength screeds with excellent technical properties.

How is anhydrite produced?

Anhydrite primarily forms through the evaporation of water in lagoons or lakes with high temperatures and low humidity, thus releasing dissolved salts. However, it can also form through the dehydration of gypsum under pressure.

MORE INFORMATION?

For all questions regarding anhydrite, we are happy to assist. Please do not hesitate to contact us – we will gladly respond.