Feldspar & Nepheline Syenite: High Chemical Resistance Fillers

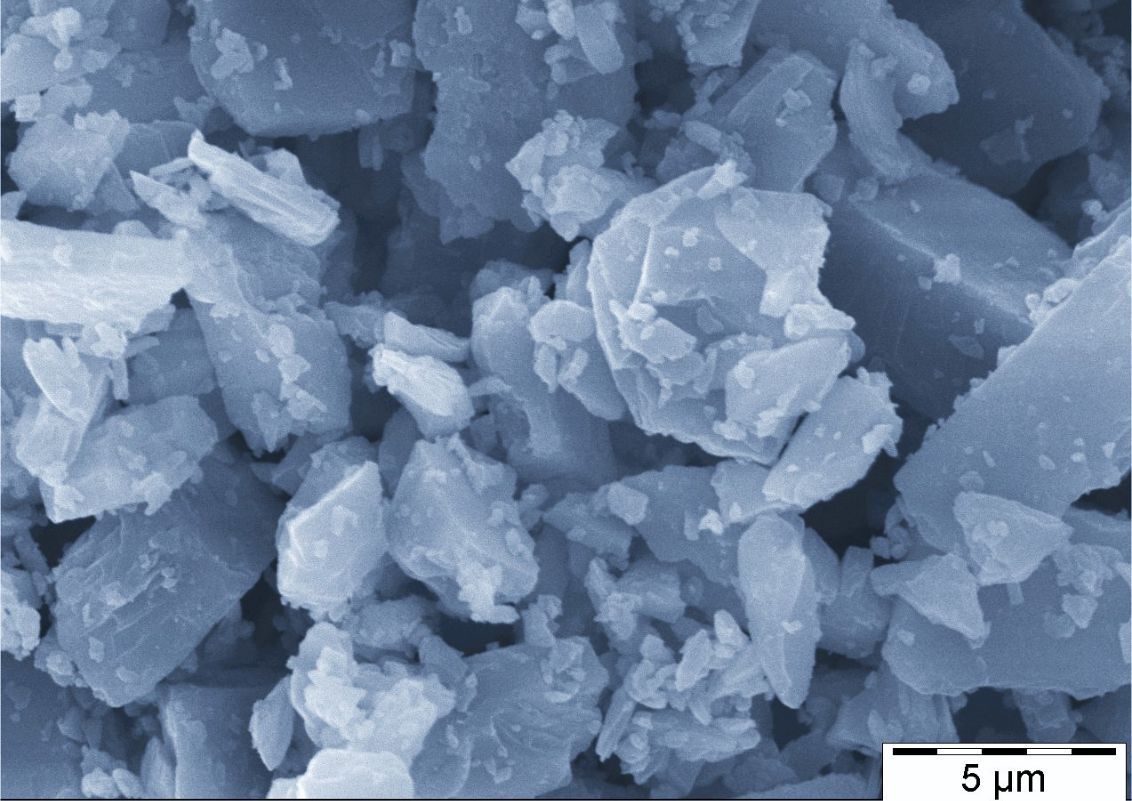

With almost 60 % by weight of the available rocks in the earth's crust, feldspars represent by far the dominant group of minerals. They are chemically resistant tectosilicates with a robust grain morphology. Feldspar belongs to the group of alkali and alkali earth metal silicates and is an essential raw material for numerous economic sectors. Its hardness and resistance make it an indispensable component in the production of ceramics, glass and as a filler in the plastics industry. Nepheline syenite is an igneous rock with a unique chemical composition.

Our range of feldspar & nepheline syenite

HPF offers a wide range of potassium and sodium feldspars. These are processed through a complex process of sieving, separating, classifying and micronizing to ensure the highest quality.

Nepheline syenite consists of feldspars and feldspar-like minerals such as albite, microcline, and nepheline. This raw mineral material does not contain any crystalline silica. Like feldspar nepheline syenite is inert and is distinguished by a hardness of 6 on the Mohs scale and high light reflection. HPF exclusively offers surface treated variants of this material.

Chemical formula

FELDSPAR

Sodium feldspar: NaAl[Si3O8]

Potassium feldspar: KAl[Si3O8]

(Na,K)Al[SiO4] (Na,K)Al[Si3O8]

MINERALOGY: SILICATES (WITH TECTOSILICATE STRUCTURE)

Feldspars exhibit crystalline structures in both the monoclinic and triclinic systems. Monoclinic crystals are typical of orthoclase, adularia, and sanidine, while microcline, as an intermediate and final member of the plagioclase series, crystallizes in the triclinic system.

HPF’s feldspar and nepheline syenite: Products of the highest quality

The products distributed by HPF bear the following brands:

MICROSPAR®

represents surface-modified feldspar

TREMINEX®

offers surface-treated types of nepheline syenite

Our feldspar and nepheline syenite – IMPORTANT RAW MATERIAL FOR POLYMER APPLICATIONS

Feldspar and nepheline syenite find multiple applications in the world of polymers, where their unique properties are utilized in various sectors:

Dental applications

The MICROSPAR® feldspar product range has proven to be particularly effective in dentistry, where it is used in prosthetics, filling materials and impression materials.

Another focal point concerns applications in the field of anti-block and films. Our special fillers offer optimized UV and IR absorption and are stable at high temperatures. Particularly suitable for LDPE (low-density polyethylene) or LLDPE (linear low-density polyethylene), the microfine feldspar powders from the MICROSPAR® range meet the highest requirements. These fillers offer exceptional anti-block properties while ensuring excellent film transparency, making them an optimal choice for demanding applications.

Paints and Coatings

Powder coatings

A type of TREMINEX® with special surface treatment opens new horizons in the world of powder coatings based on polyester resin. The exceptional properties of this special filler offer a clear added value:

• excellent mechanical properties

• good incorporation into the formulation thanks to surface treatment

• better results in salt spray and condensation tests on steel

• cost savings due to higher yield

Industrial paints – HPF Minerals

Wood paints

The advantages of a surface treated nepheline syenite of the TREMINEX® 958 range in parquet paints include:

• improved scratch resistance

• excellent transparency

THE TRADITIONAL USE OF FELDSPAR AND NEPHELINE SYENITE

The traditional use of feldspar and nepheline syenite extends across a wide range of industries. Feldspar, as a significant component, plays a key role in the production of ceramics and porcelain. Its chemical resistance and ability to aid in melting and sintering make it indispensable in glass production.

The versatility of feldspar is also evident in the insulation industry, where it is used in the production of mineral wool. Additionally, feldspar finds its application in the jewelry industry, where it is used to produce gemstones and decorative elements; in this context, labradorites are particularly suitable. Nepheline syenite is used in the art industry. Its pigments and glazes are appreciated for creating unique artistic expressions.

The properties of feldspar

Feldspar, being the predominant mineral in the earth's crust, plays a central role in various industrial applications and is valued for its unique properties. The name of this mineral is based on its cleavage and ability to detach fine lamellae under mechanical action.

Feldspar minerals are found in a variety of rock types, including eruptive, metamorphic, and sedimentary formations. This mineral variety is presented as a chemically resistant tectosilicate with a thick and tabular grain morphology. European deposits are often characterized by mixed feldspars composed of potassium and sodium feldspar. An example of pure and homogeneous potassium feldspars comes from the Amberger Kaolinwerke in Hirschau, a company of the Quarzwerke group; they are a significant component of HPF's product range.

Through complex processing processes, HPF offers both potassium and sodium feldspars that meet the highest quality standards. These high-quality fillers, with their chemical resistance, play a crucial role in various industrial processes, particularly in the production of ceramics, glass, and other high-quality materials, such as for the plastics and dental industry.

The properties of NEPHELINE SYENITE

Nepheline syenite consists of feldspars and feldspar-like minerals such as albite, microcline, and nepheline. This raw mineral material does not contain crystalline quartz. Nepheline syenite is inert and, like feldspar, is distinguished by its remarkable hardness and a high degree of whiteness.

WORLD DEPOSITS OF FELDSPAR AND NEPHELINE SYENITE

Feldspar and nepheline syenite are widely distributed raw mineral materials found in various geological formations worldwide.

Feldspar is globally found in various rock types. Major deposits can be found in different countries such as China, India, Turkey, Italy, Brazil, and the United States, as well as Germany. These countries host vast deposits, exploited through mining to meet the growing demand in the ceramics, glass, and construction materials industry.

Nepheline syenite is also widely distributed, with significant deposits in countries such as Canada, Russia, Norway, and India. These regions are characterized by magmatic processes leading to the formation of nepheline syenite, making it a sought-after raw material for the production of pigments, glazes, and other applications.

EXTRACTION AND PRODUCTION OF FELDSPAR, AS EXEMPLIFIED BY HIRSCHAU/SCHNAITTENBACH

In Germany, feldspar is extracted from the rich deposits of Hirschau/Schnaittenbach. Here, vast feldspar deposits are made accessible through careful mining. The extraction takes place in several stages, starting with the identification and extraction of deposits. State-of-the-art technologies and geological expertise are used to locate deposits and extract high-quality feldspar.

The actual extraction involves separating feldspar from rock layers. In Hirschau/Schnaittenbach, the quality of feldspar is evident in its purity and composition, making it a sought-after raw material for various industries.

Afterward, feldspar is carefully processed and reduced to the desired grain size. This process is crucial to meet the specific demands of various applications, whether in the production of ceramics, glass or other industrial sectors.

The extraction of nepheline syenite follows a similar process. This type of magmatic rock, composed of feldspars, albite, microcline, and nepheline is extracted and carefully processed to exploit its multiple properties.

Mindful and sustainable extraction is a central principle. State-of-the-art technologies are used to minimize environmental impact and ensure ecological sustainability.

THE HISTORY OF FELDSPAR AND NEPHELINE SYENITE

Feldspar has a long history. Already in antiquity and ancient China, it was used for the production of ceramics and glass. Its ability to melt at high temperatures and create a smooth and shiny surface made it a valuable raw material in art and craftsmanship. Over time, the use of feldspar has further diversified, finding applications in modern industries, from porcelain and ceramics production to glass production to plastics production.

Nepheline syenite also has an interesting and impressive history. The discovery and use of this type of rock are closely related to advances in mining and processing technology. In the history of art, nepheline syenite plays a role as a pigment and material for glazes.

Useful information about other industrial fillers

Use our informative guide to learn more about other industrial fillers. We are happy to provide you with information in person as well.

FAQ

What properties do feldspar & nepheline syenite have?

Feldspar is a group of tectosilicate minerals with a Mohs hardness of 6 – 6.5 and a density of about 2.6 g/cm³. They are chemically resistant and available in colors such as white, gray, green, or red. Nepheline syenite is an igneous rock composed mainly of nepheline and alkali feldspar. It has a hardness of 6 on the Mohs scale and a density of about 2.6 g/cm³. This rock is inert and does not contain crystalline silica.

In which applications are feldspar & nepheline syenite used?

Feldspar is mainly used in the ceramics and glass industry to lower the melting temperature and increase the strength of products. Additionally, it is used as a filler in the plastics industry. Nepheline syenite is used in the production of porcelain and ceramics, as an anti-block additive in plastic films, and as a filler in wood and decor paints.

What benefits do feldspar & nepheline syenite have?

In ceramics and glass production, feldspar acts as a flux, reducing the melting temperature and improving the strength of the final products. In the plastics industry, it increases the mechanical resistance and stability of materials. Nepheline syenite improves scratch resistance and transparency in paints and prevents layer adhesion in plastic films.

How are feldspar & nepheline syenite produced?

Feldspar is extracted from feldspar-containing rocks, followed by crushing, cleaning, and classification to achieve the desired grain size. Nepheline syenite is extracted and processed similarly, using special procedures to remove impurities and ensure the purity and quality of the final product.

MORE INFORMATION?

For all questions regarding feldspar & nepheline syenite, we are happy to assist you. Please do not hesitate to contact us – we will gladly respond.