Surface Modification for Durable and High-Performance Materials

Surface treatment is an innovative surface modification process for mineral fillers used in numerous industries. This process improves the adhesion between fillers and polymers, ensuring greater mechanical strength, durability, and workability of the final products.

The targeted use of silanes creates a lasting chemical bond that offers significant advantages, such as increased longevity and optimized material properties.

Surface treatment of mineral fillers is an indispensable technology for enhancing final products in various sectors such as construction, plastic processing, electronics, paints and coatings, and even medicine. The surface treatment meets the high requirements of modern materials and significantly contributes to sustainable high-performance polymer solutions. Here you will find all information about the surface treatment, the underlying processes, and the numerous application possibilities of surface treated products.

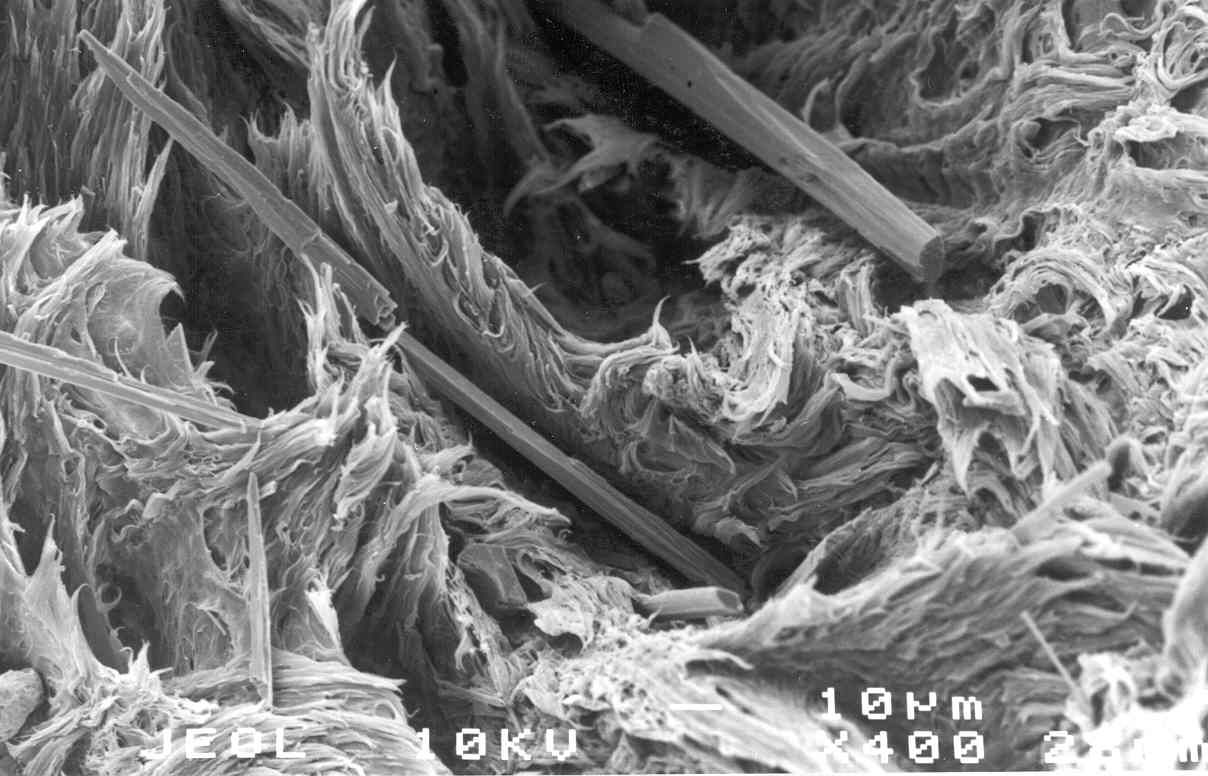

Wollastonit TREMIN® 939 incorporated into polymer after fracture

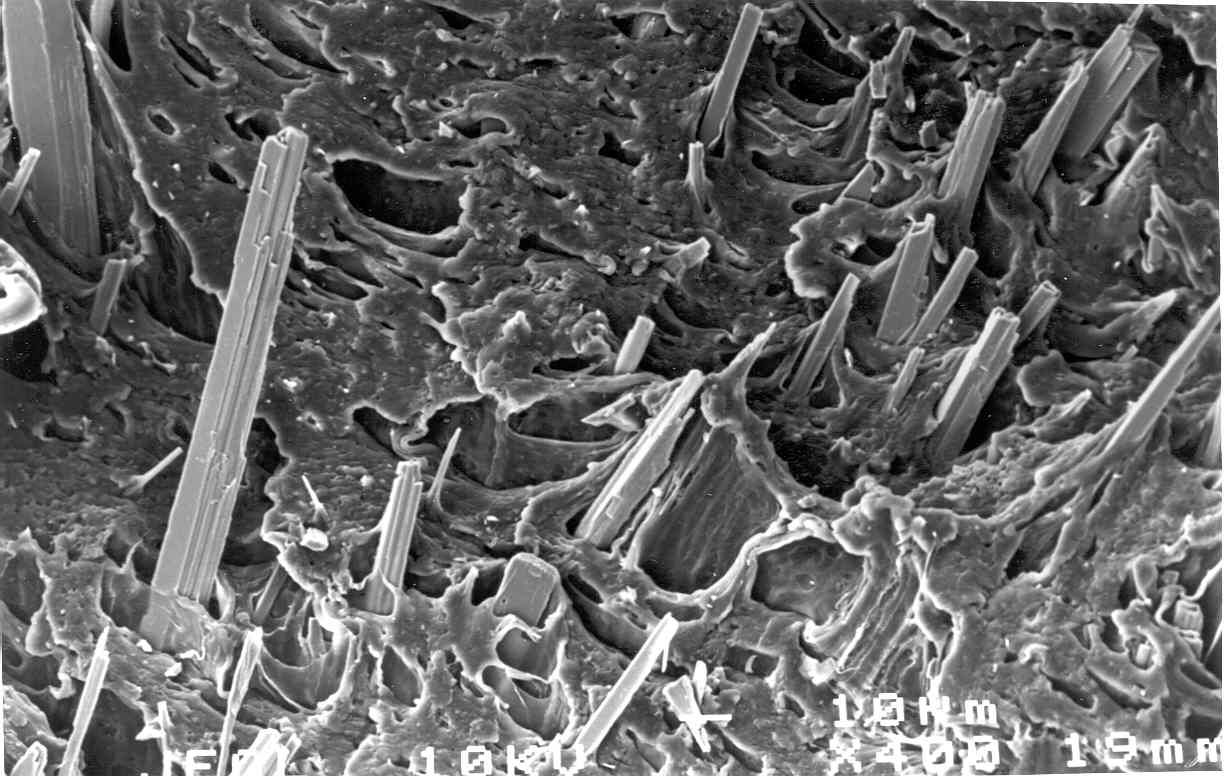

Surface treated Wollastonite TREMIN® 939 incorporated into polymer after fracture

The Excellent Chemical Properties of Silanes

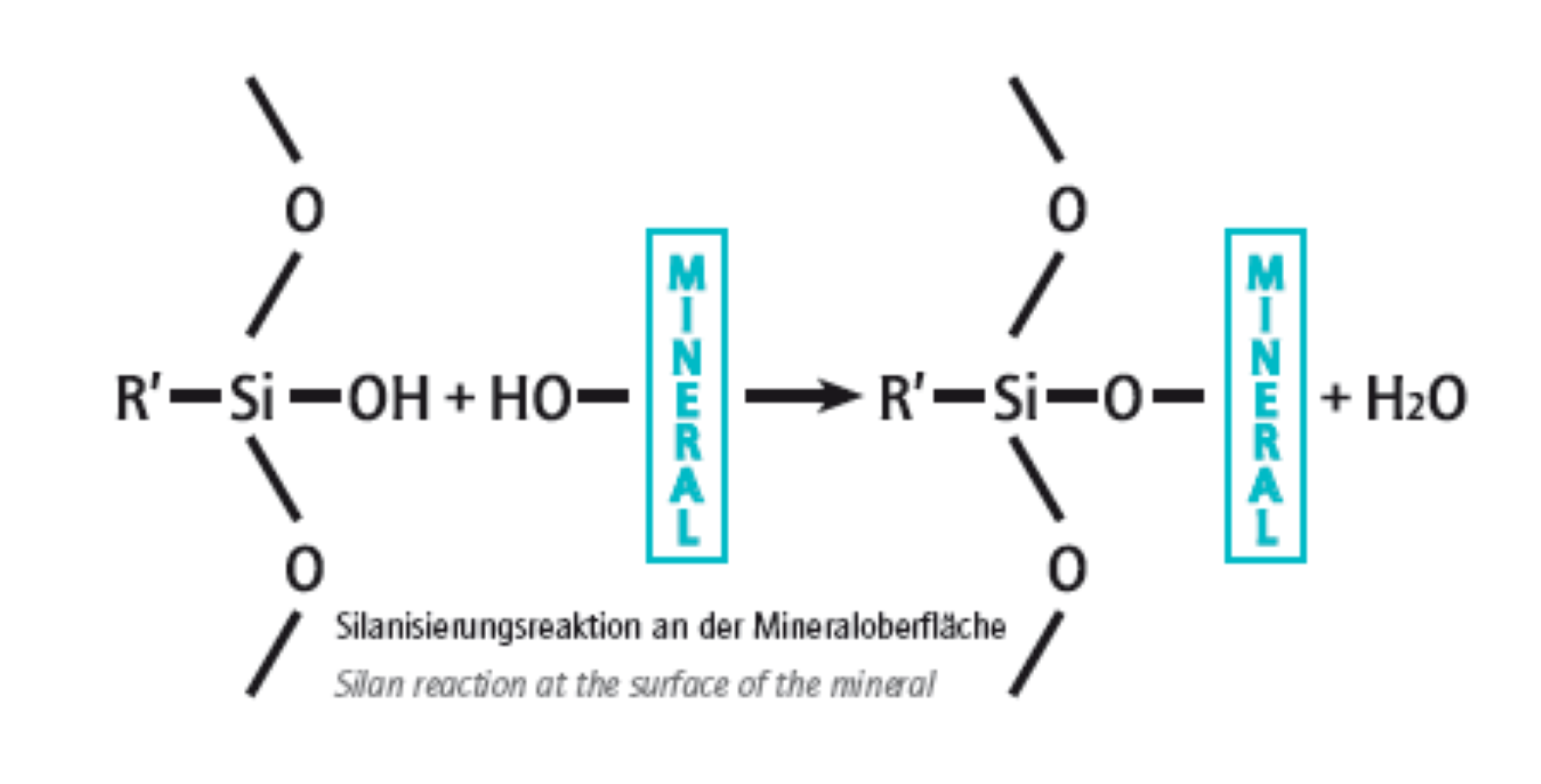

Silanes are chemical compounds with a unique structure, consisting of a central silicon atom covalently bonded to both organic groups and reactive groups (e.g., chlorinated groups). This combination makes silanes bifunctional and allows for versatile use in surface modification.

The reactive groups hydrolyze upon contact with water, forming silanol groups (Si-OH), which can chemically bond to surfaces rich in hydroxyl groups such as glass, metals, or mineral fillers. At the same time, the organic groups remain intact and can interact with polymers, facilitating integration into polymer materials.

Through this reaction, silanes create a lasting chemical modification on the treated surface. This enhances the adhesion between the filler and the polymer, providing the material with additional properties such as increased strength, improved mechanical stability, and optimized workability.

Silanes Shortly Explained

Silanes are bifunctional compounds consisting of stable organofunctional groups and hydrolyzable reactive groups. The hydrolyzable group bonds with the filler surface, while the organofunctional groups harmonize with the polymer.

A decisive advantage: when surface treated fillers are directly incorporated into a polymer system, condensation by-products like ethanol and water are released during the mineral coating process. With in-situ surface treatment, these remain in the polymer system and can weaken it.

Advantages of Direct Surface treatment

The direct surface treatment offers numerous advantages in modifying mineral fillers and enhancing polymer materials. During the production of mineral powders, hydroxyl groups are formed through reactions between terminal silicon and oxygen atoms with air moisture. These hydroxyl groups bind water molecules, which are difficult to remove even with intensive drying processes, weakening the bond between the filler and polymer matrix.

Direct surface treatment of fillers solves this problem, as condensation by-products like ethanol and water can escape during coating. Unlike subsequent in-situ surface treament, there are no unwanted by-products left in the polymer system, significantly improving its stability and performance.

Furthermore, surface modification with silanes facilitates the incorporation of fillers into polymer systems and ensures optimal bonding between polymer and filler.

This leads to a range of exceptional material properties, such as:

- high resistance to weathering and chemicals

- improved resistance to thermal deformation and high temperatures

- enhanced resistance to boiling water and scratches

- resistance to cathodic delamination

- excellent paint adhesion and the possibility of achieving glossy finishes

- high mechanical strength and toughness

- optimized filler levels and workability

These properties make surface treatment a key technology in producing functional fillers for high-performance and durable polymer materials.

Types of surface treatment

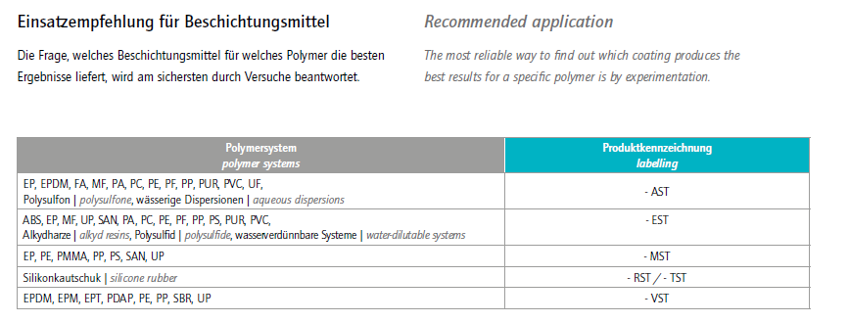

The choice of coating medium depends on the polymer material to be optimized.

The table shows recommendations for using coating media based on the polymer system. The best results are determined more reliably through testing.

Hydrophobic mineral surface thanks to surface treatment

For All Challenges, the Right Solution

Surface treated fillers improve the mechanical properties of plastics, increase paint resistance, and ensure maximum reliability in electrical and electronic applications. Whether in automotive, construction, electrical engineering, or even medicine, the usage possibilities are diverse and future-oriented.

Summary of Application Areas for Silanized Fillers

- Plastic parts in the automotive industry

- Technical thermoplastics

- Industrial paints and clear coating systems

- Outdoor applications of electrical and high-voltage insulators

- Epoxy resin systems and electronic components

- Dental impression materials

- Silicone sealants

- Sanitary equipment in PMMA and UP

- Kitchen worktops and sinks

Contact us for more information on the benefits of surface treated fillers in your application and to develop tailored solutions.

Minerals Suitable for surface treatment

Surface treatment is a proven method for surface modification of mineral fillers to improve their compatibility with polymers and optimize specific material properties. Below are listed suitable minerals with their typical areas of application:

Quartz: High-purity silicon dioxide with exceptional hardness and chemical resistance, ideal for glass, electrical applications, paints and coatings, and construction chemicals.

Cristobalite: Calcined quartz with a high degree of whiteness, frequently used in paints and coatings, artificial stone, and dental materials.

Fused silica: Amorphous modification of quartz with extremely low thermal expansion for precise applications in electronics and electrical insulation, epoxy resin systems, investment casting, and motor encapsulation.

Wollastonite: Natural calcium silicate with excellent reinforcing properties, ideal for ceramics, glass, building materials, technical plastics, powder coatings, and turbine blade coatings.

Kaolin: Fine, plate-shaped natural mineral with smoothing properties, popular in the paper industry. Kaolin is also suitable for use in technical plastics, ceramics, paints and coatings, and rubber.

Feldspar: Chemically resistant chain silicate with coarse grain morphology, used in glass and ceramic products and as a filler in paints and coatings, plastic films, and dental applications.

Mica: Layered mineral with excellent barrier properties due to its pronounced plate structure. The muscovite and phlogopite mica are suitable for use in paints and coatings, high-temperature applications, technical plastic parts, and cosmetics.

Nepheline syenite: Composed of feldspar-like minerals and free of crystalline quartz. The mineral has transparent properties and mechanical resistance and is used in clear coat systems and plastic films.

Corundum: Synthetically produced and almost as hard as diamond. Due to this extraordinary hardness, the mineral is ideal for abrasives, refractory materials, and surface processing.

Talc: The softest filler in the world belongs to the phyllosilicate group. Thanks to its water-repellent properties, talc is widely applicable in plastics, paints and coatings, as well as in pharmaceuticals and cosmetics.

Aluminum hydroxide: Synthetically produced, it is a flame retardant filler with high chemical stability for the plastics industry, electronics, paints and coatings, but also for textile applications.

Anhydrite: As anhydrous sulfate, the mineral is widely usable in construction chemistry and, thanks to its transparent properties, particularly in clear coat systems.

The surface treatment of these minerals optimizes their interaction with polymers and expands their usage possibilities in various industries.

Environmental Compatibility and Sustainability of Surface treatment

Modern silane compounds are environmentally friendly, produce low emissions, and are manufactured in an energy-efficient processing manner. As a sustainable solution for surface modification, surface treatment enables the production of durable products and reduces resource consumption, decreasing the industry's ecological footprint. It improves material resistance to moisture, chemicals, and mechanical stress, thereby reducing the need for repairs and wear susceptibility.

Innovative Applications for surface treated products

Research focuses on innovative silanes to further improve the adhesion between filler and polymer, increase the strength and durability of products and improve efficiency and sustainability.

Application Areas:

- Construction

- Vehicle manufacturing

- Aeronautics

- Wind energy

- Rubber and plastic processing

- Paints and coatings

- Electronics

- Adhesives and sealants

- Cosmetics

- Medicine

FAQ

What are the benefits of surface treatment?

Surface treatment improves adhesion between fillers and polymers, significantly increasing the mechanical properties and durability of final products. It reduces unwanted by-products like ethanol and water that could weaken the polymer system, ensuring durable and high-performance materials.

Which materials can be surface treated?

Suitable materials include minerals such as quartz, cristobalite, wollastonite, kaolin, feldspar, mica, nepheline syenite, corundum, talc, aluminum hydroxide, and anhydrite.

In which applications can surface treated products be used?

Surface treated fillers are used in numerous industries, including:

- The automotive industry (plastic parts, engineered plastics)

- Electrical engineering (outdoor applications of medium and high-voltage insulators, electronic components)

- Construction (industrial paints, clear coat systems, epoxy resin systems)

- Medicine and cosmetics (dental impression materials, sanitary equipment)

- Consumer goods (kitchen worktops, sinks, silicone sealants)

- High-tech applications (semiconductors, wind turbines, aeronautics)

How is the industry's use affected by surface treated of fillers?

Surface treatment optimizes the compatibility of fillers with polymers and significantly improves the properties of final products. It leads to more durable materials with increased stability and reliability, making it a key process in the production of innovative materials for demanding applications such as construction, electronics, and vehicle manufacturing.

More Information

For any questions regarding surface treatment, please feel free to contact us. We will be happy to respond.