White fused alumina: Extreme hardness

Aluminum oxide (also known as white fused alumina) is one of the most fascinating minerals due to its unique properties. In its pure form, it is completely transparent, but due to chemical impurities (e.g., traces of chromium, iron, or titanium), it takes on various colors and shines like a precious ruby or sapphire.

For multiple applications and industrial processes, white fused alumina is instead produced synthetically and at significantly lower costs, for example under the SEPASIL® brand. With a Mohs hardness of 9 on a scale that goes up to 10, it is almost as hard as a diamond and completely transparent. This makes artificial white fused alumina extremely resistant to scratches, and, thanks to its extraordinary hardness, abrasion resistance, and high-temperature resistance, it is ideal as an abrasive material, for sandblasting, and as a cutting tool.

It is also used in the production of highly abrasion-resistant coatings and laminates, as well as a high-temperature insulator in industry.

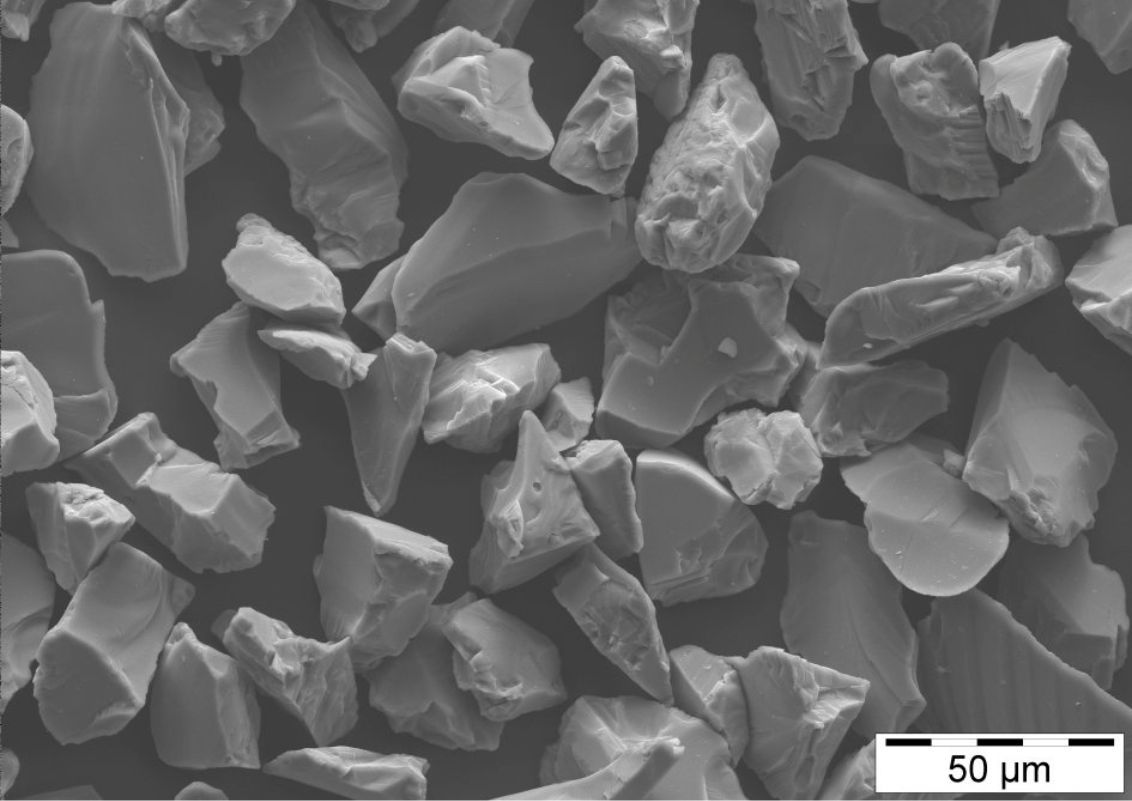

Under the scanning electron microscope

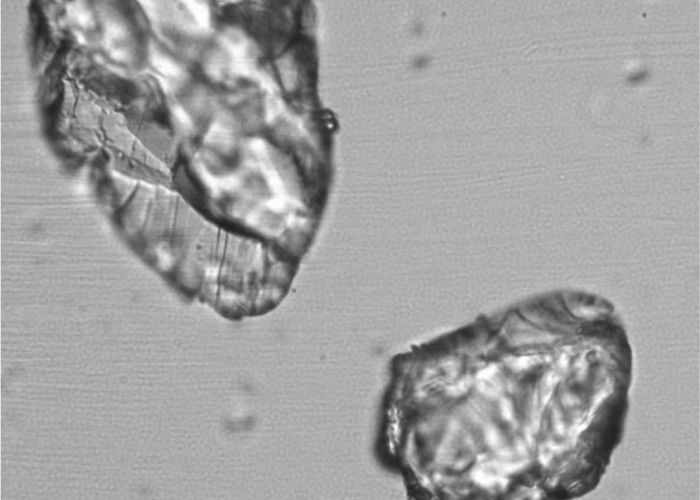

Under the optical microscope, the transparency of the mineral can be seen

Technical properties

- Density: 3.95 g/cm³

- Hardness: 9 (Mohs), 2060 (Vickers)

- Chemical inert

- Behaves transparently in many binding systems

- Very narrow particle size distribution

- Grain shape rounded or fractured depending on processing

Chemical formula

AI2O3

White fused alumina is composed of 99% aluminum oxide α.

Mineralogy

White fused alumina is a relatively common mineral and belongs to the oxides. It crystallizes in the trigonal crystal system. Today, natural corundum is almost exclusively used as a gemstone, while the industry uses synthetic white fused alumina such as HPF's SEPASIL® EK. Synthetic white fused alumina is produced by melting aluminum oxide in an electric arc furnace. Artificial production ensures uniform and standardized quality and availability. This is a clear advantage in industrial applications as it allows specific requirements to be met.

Classification: To meet various applications, it is useful to classify the product according to internationally recognized standards. This classification is based on particle size, purity, and other specific properties. The definition of these industrial standards is carried out by the Federation of European Producers of Abrasives (FEPA). This allows the quality and suitability of the corundum for various applications to be objectively evaluated.

HPF white fused alumina: Highest quality products

HPF products are known under the brand name:

SEPASIL®

fine white fused alumina powders can be supplied uncoated and surface treated/coated

SURFACE TREATMENT

The surface treatment is particularly important in the production of composite materials, plastics, and coatings. This process optimizes adhesion between the white fused alumina and the polymer matrix, improving the mechanical properties of the final product. However, for traditional uses of white fused alumina, such as abrasive and cutting tools or in the production of refractory materials, no finishing is necessary.

Our white fused alumina – an important raw material for polymer applications

White fused alumina is extremely scratch-resistant, and, thanks to its extraordinary hardness, abrasion resistance, and high-temperature resistance, it is ideal as an abrasive material, for sandblasting, and as a cutting tool.

Paints and coatings

- highly abrasion-resistant wood and decorative coatings

- laminates

White fused alumina significantly improves scratch resistance in 100% UV paints for furniture and wood surfaces.

Wood and decorative coatings – HPF Minerals

Plastics

- cast resin and high-voltage insulators

Thanks to its electrical insulation capacity, corundum is ideal for use in electrical engineering.

SEPASIL® EK for highly stressed wood surfaces

The multiple properties of white fused alumina

White fused alumina impresses with a number of unique properties that explain its multiple applications in the industry:

Hardness

White fused alumina has a Mohs hardness of 9. Only diamond (Mohs hardness 10) and a few other rare minerals are harder. This hardness makes corundum extremely scratch and wear-resistant, making it ideal for abrasive applications.

Colorless and transparent

Unlike other natural variants such as ruby or sapphire, synthetic white fused alumina is completely colorless and transparent.

Chemical resistance

White fused alumina is chemical inert and thus resistant to most acids and bases. Thanks to this resistance and stability, it is suitable for industrial applications even in environments with aggressive chemicals.

Electrical insulation

A property that makes it ideal for use in electrical engineering, for example as an insulating material.

The story of white fused alumina

The mineral was mentioned about 2,000 years ago by the Roman naturalist Pliny the Elder in his encyclopedic work on natural history "Naturalis historia", then known as Adamas siderites.

In 1709, an English geologist used the term Corinvindum, inspired by the Tamil and Sanskrit languages. He had observed that this mineral was used in India to polish crystals, an early example of use as an abrasive and polisher.

Around 1800, analyses revealed that rubies and sapphires are chemically identical to white fused alumina, differing only in color. In the 19th century, researchers reported discoveries in various parts of the world, from China to India to Philadelphia.

A turning point in the history of white fused alumina was the synthetic production as a substitute for the expensive diamond, achieved at the end of the 19th century by melting aluminum oxide in an electric arc furnace at 2,120°C. This electric melting process is still used today in the production of synthetic white fused alumina. The global production amounts to about 1,300,000 tons per year.

Today, natural white fused alumina is almost exclusively used as a gemstone, while the industry uses synthetic white fused alumina such as SEPASIL®. White fused alumina remains a key element in many industrial processes.

A multi-step process: the production of white fused alumina

The production of white fused alumina takes place through a multi-step process, up to optional refinement if necessary.

Raw material extraction: The base material for white fused alumina production is aluminum oxide, obtained from bauxite, alumina, or other aluminum-containing minerals.

Cleaning and crushing: In this phase, impurities are removed, and the desired particle size is achieved.

Melting: The purified aluminum oxide is melted at temperatures of 2,120°C in electric arc furnaces.

Crystallization: The molten mass must cool slowly to allow crystal formation, developing the necessary crystal structure and hardness.

Grinding and polishing: Subsequently, the white fused alumina is ground into various shapes and sizes, achieving the desired final shape and improving surface quality.

Classification and sorting: At this stage, the ground white fused alumina is classified and sorted by size and quality, ensuring that the final products meet all specific requirements based on the desired application.

Quality control and assurance: Continuous control and quality assurance during all stages of the process ensure that the white fused alumina meets all standards and requirements. It is essential to monitor particle size, purity, and crystal structure using modern analysis and testing techniques.

Packaging and storage: White fused alumina is insensitive to temperature and light variations. However, the product must be carefully packaged and stored to avoid moisture or contamination by foreign particles.

The traditional usage of white fused alumina

As varied as the mineral itself, the use of white fused alumina is extremely versatile. The range of applications extends across numerous sectors and industrial processes thanks to its extraordinary properties.

Jewelry: White fused alumina ("white sapphire") is a valid economical alternative to diamonds in the production of rings and pendants as a clear and colorless stone.

Abrasives and sandblasting materials: With a Mohs hardness of 9, white fused alumina is suitable for the production of abrasives, grinding discs, and cutting tools, as well as for use in metalworking, the glass industry, and other manufacturing processes.

More information.

Ceramic and glass industry: Thanks to its hardness, white fused alumina is used as an abrasive and polisher for ceramics and glass.

High-performance ceramics: White fused alumina is also used in the production of sanitary products, tableware, and non-slip tiles.

Thermal insulation: White fused alumina is extremely heat-resistant and is therefore used for thermal insulation.

Precision tools: The hardness and transparency make the white fused alumina an important raw material in the production of watches, measuring instruments, and precision tools.

FAQ

What properties does white fused alumina have?

Synthetic white fused alumina is a variant of the mineral corundum (Al2O3) and is characterized by a Mohs hardness of 9, making it one of the hardest known materials after diamond. It is chemically inert, heat-resistant, and has a high density of about 3.9-4.1 g/cm³. Depending on the purity and impurities, its color ranges from colorless to pink to brown.

In which applications is white fused alumina used?

Thanks to its extraordinary hardness and resistance, white fused alumina is used in numerous industrial applications. It is used as an abrasive in sandpaper, cutting discs, and polishing tools. In addition, it is used as an additive in hard concretes and ceramic tiles to increase their slip resistance.

What benefits does white fused alumina have?

In certain applications, white fused alumina acts due to its high abrasiveness and mechanical wear resistance. As an abrasive, it allows efficient material removal and precise polishing. In refractory materials, it increases resistance to high temperatures and the durability of the products. Its chemical inertness also ensures stability in corrosive environments.

How is white fused alumina produced?

The production of synthetic white fused alumina involves melting high-purity calcined alumina in electric arc furnaces at temperatures of about 2,000°C. This process leads to the formation of aluminum oxide crystals, which are then cooled and crushed into different grain sizes depending on the intended use. Adding chromium oxide can produce different color variants such as pink or ruby red.

MORE INFORMATION?

For any questions regarding white fused alumina, we are at your disposal. Please do not hesitate to contact us – we will be happy to respond.